Detailed Product Description

Basic Info

| Model No.: KYT | Working Speed: 8-15 Meter/min |

| Control System: PLC | Blade Material: Cr12 |

| Warranty: 24 Months | After Sale Service: Engineer Available To Service Abroad |

| Thickness Material: 0.7-1.2mm | Product Name: Fire Rated Shutter Door Making Machine |

| Cutting System: Hydraulic Cutting | RAW MATERIAL: Galvanized Steel, Aluminium Plate |

| Certificate: ISO9001/CE | |

Additional Info

| Packaging: Seaworthy packing | Productivity: 30 sets per month |

| Brand: KYT | Transportation: Ocean |

| Place of Origin: China | Supply Ability: 30 sets per month |

| Certificate: ISO9000/CE | HS Code: 8455221000 |

| Port: Tianjin Port | |

Product Description

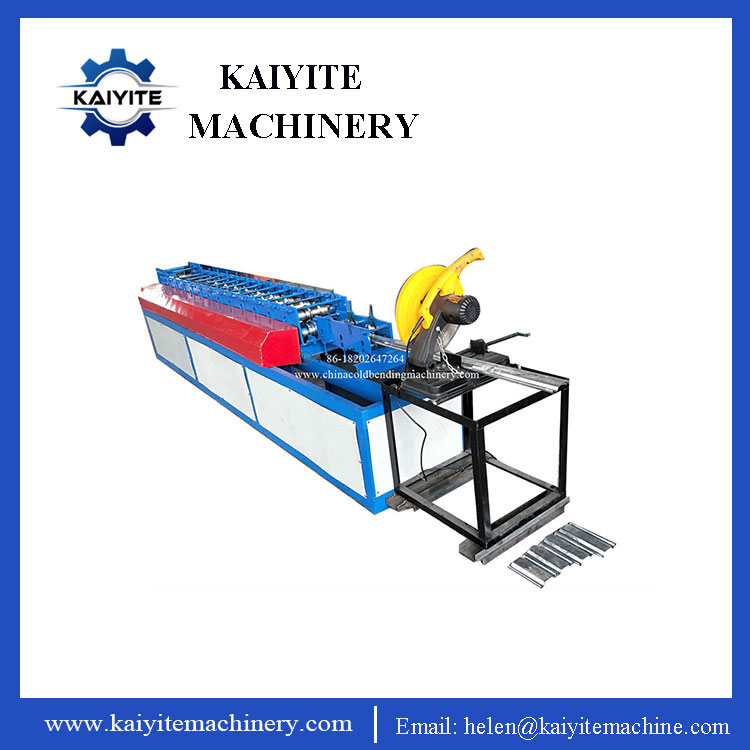

Wind Resistance Roller Shutter Door Cold Roll Forming Machine

Quality is the key to a long-term development of a company . We do not compare prices with other manufacturers . We compare quality with quality . Our company is not as eager to find the expansion of the factory as other companies , our main financial and energy investment in the improvement of product quality . Therefore , we are studying the details and constantly improving our own requirements in order to better meet the needs of our customers .

Some roller shutter door profile has the following three kind of hole . Different hole has the different forming method . For the first one , the hole mould and the cutting mould is the same one . It means that this kind of hole will be made when it is cut . For the second hole , The machine will have a punching unit . The distance of the hole can be adjustable by the PLC control box .

In some country , the embossing shutter door machine is very popular . The embossing flower on the shutter door profile is made by the roller . In the shutter door equipment , there is a pair of the roller which located at the first station .

The coil enter into the feeding table then it goes to the embossing roller , after the cold pressing , the flower has been fiished . There are various of flower shapes , we can make it according to client choice .

Technical Specification for The Roller Shutter Door Roll Forming Machine

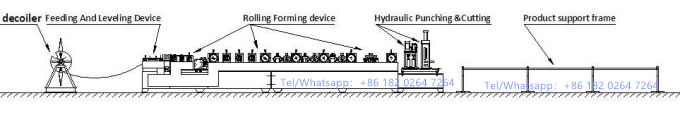

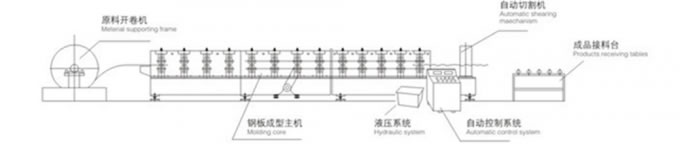

(1) 5 tons hydraulic un-coiler:

Hydraulic motor drives. One single-head structure. It has a pressing arm to prevent the coil loose.

Electric uncoiling, hydraulic motor tenses the coil inner.

The max. coil inner-diameter is 508mm.

The max. coil outter-diameter is 1200mm.

The max. width of coil is 1250mm.

The max. capacity is 5 tons.

(2) Roll-Forming M/C :

Welded steel structure base, chains transmit, motor drives it. The machine include the filming device .

The roller is designed by Germany software COPRA, and has FEA analysis, which can promise the product precision.

Material of Roller: 45#, with hard chrome coated, polishing,

Voltage:380V/50Hz

(3) Hydraulic pressing/ Cutting :

Stop to press, Stop to cut, Post cut .Cutting tool material: Cr12, pressing tool material:40Cr.

Tolerance of the cutting length ±2mm.

(4) Product Rack

It is 2 parts, 6 meters total.

Un-powered.

(5) Hydraulic System

It offers power for the cutter.

(6) Electrical System :

It uses Siemens PLC system to control the whole line. It can measure and cut the length automatically. Frequency adjusts the speed and it has the self-control speed function.

Human-machine screen, touch screen control. The length can be set in touch screen freely and operation is simple.

The surround connecting wires adopts aviation socket or fast-speed plug.

Company information

Kaiyite machinery is a leading manufacture of roll forming machine . We know well the particular requirements for the customers from different countries , and have an outstanding export team who will take your requests . Our experts and skilled workers complete the work with great precision .We provide an extensive line of products , including roller Shutter Door Roll Forming Machine , Door Frame Machine , Roof And Wall Panel Roll Forming Machine , Double Layer Roll Forming Machine , Floor Deck Roll Forming Machine ,C / Z / U Purlin Roll Forming Machine , Stud And Track Roll Forming Machine , Ridge Cap Roll Forming Machine , Downspout Pipe Roll Forming Machine , Shearing Machine And Bending Machine , Slitting And Cutting Machine .

Contact information for the Roller Shutter Forming Machine