Detailed Product Description

Basic Info

| Model No.: KYT | Tile Type: Colored Steel |

| Certification: SGS, CE, ISO | Condition: New |

| Customized: Customized | Usage: Other |

| Transmission Method: Hydraulic Pressure | Warranty: 18 Months |

| After Sale Service: Engineer Available To Service Abroad | Material: Galvanized Steel, Aluminium Plate |

| Package: Packed With Water Proof Paper | Delivery Time: Within 35 Days |

| Capacity: 8-15m/min | Name: Twin Lath Roller Shutter Slat Machine |

| Certificate: ISO9001/CE | Loading: 20 Feet Container |

Additional Info

| Packaging: Seaworthy packing | Productivity: 30 sets per month |

| Brand: KYT | Transportation: Ocean,Land |

| Place of Origin: China | Supply Ability: 30 sets per month |

| Certificate: ISO9000/CE | HS Code: 8455221000 |

| Port: Tianjin Port | |

Product Description

Twin Lath Roller Shutter Slat Roll Forming Machinery

This Twin Lath Roller Shutter Slat Roll Forming Machinery is full automatic . There are two kind of cutting system for the metal door roller shutter roll forming machine . One is hydraulic mold cutting , another one is fly saw cutting system . The hydraulic mold cutting is no burr , and no mars . But once broken , it is not easy to repair . For the fly saw cutting , it can cut many different panel , and easy to change the saw web .

Main Detail Of Anti-Wind Shutter Door Roll Forming Machine

* Suitable Material: Colored Steel Plate, Galvanized Board, Aluminum Plate;

* Thickness: 0.3mm – 1.0mm;

*Driving way: By Chain

* Roller station: 12 rows;

* Diameter of shaft: ¢38mm, 45# steel;

* Roller material: 45# steel;

* Frame: 350 H steel;

* Operate: Manual and Automatic;

* Working speed: 8-10 m/min;

* Size (L*W*H): about 6200*1250*1510 mm;

* Thickness of Wall Panel:14mm

* Motor power: 3 Kw

* Hydraulic power: 3 Kw;

* Cutting Type: Hydraulic Cutting;

* Material of Blade: Cr12

* Voltage: 380V 50Hz 3Phases or Customization;

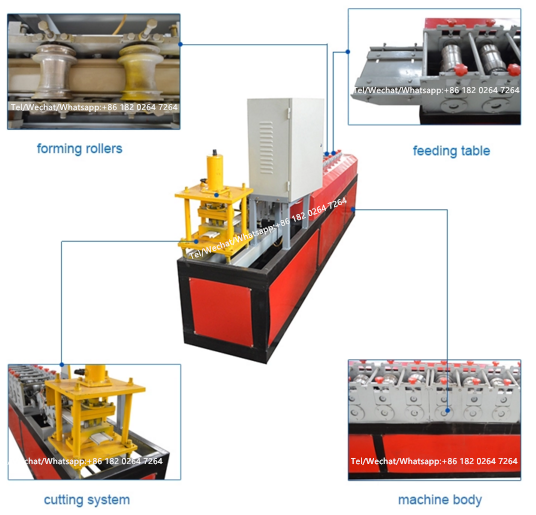

Detail Pictures Of Machine

Working Flow

Decoiler — Feeding Table — Main Roll Forming Machine — PLC Control System — Hydraulic Cutting Device — Product Receiving Table

Component Of Anti-Wind Shutter Door Roll Forming Machine

* Manual Deciler………………………………..1 Unit

* Main roll forming system………………………..1 Unit

* Hydraulic system…………………………….1 Unit

* PLC Control Cabinet………………………………1 Unit

* Discharge table…………………….2 Unit

* Spare Part…………….1 Unit

Advance of Shutter Door Strip Roll Forming Machine

* High performance * No noise * Low cost

* 24 month’s warranty * Long working life * Easy to operate

* High quality * Full Automatic * Pass ISO9001/CE

* Accurate

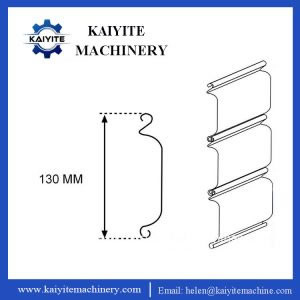

Finished Shutter Door Strip

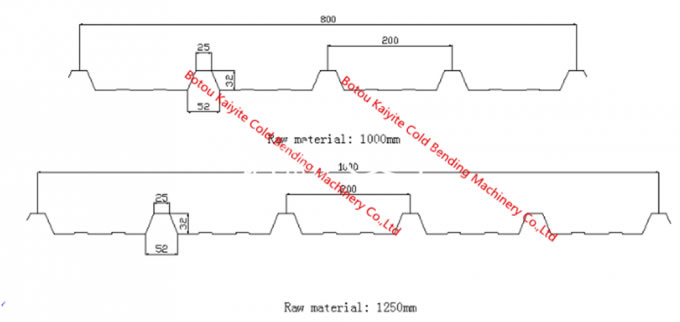

More Different Shape Of Shutter Door Drawing

Application Of Twin Lath Roller Shutter Slat Roll Forming Machinery

The products produced by Twin Lath Roller Shutter Slat Roll Forming Machinery are bright in colored, against fading, resistant to rust, and be widely used in shops, working departments, warehouses, and fire partition. Its strength is three times higher than aluminum alloy door.

Contact Us

24 hourse service the world .

Your kindly inquiry or samply are warmly welcome .

If you want to learn more about this machine or has any questions , please contact us freely .