Detailed Product Description

Basic Info

| Model No.: KYT | Tile Type: Colored Steel |

| Certification: SGS, CE, ISO | Condition: New |

| Customized: Customized | Usage: Other |

| Transmission Method: Electric | After Sale Service: Engineer Available To Service Abroad |

| Package: Packed With Water Proof Paper | Delivery Time: Within 35 Days |

| Capacity: 8-12m/min | Warranty: 5 Years |

| Weight: About 2 Tons | Operate: By PLC |

| Certificate: ISO9001/CE/SGS | Operate Type: Automatic And Manual (Two Type) |

| Name: Shutter Door Strip Stamping Machine | |

Additional Info

| Packaging: Seaworthy packing | Productivity: 30 sets per month |

| Brand: KYT | Transportation: Ocean,Land,Air |

| Place of Origin: China | Supply Ability: 30 sets per month |

| Certificate: ISO9000/CE | HS Code: 8455221000 |

| Port: Tianjin Port | |

Product Description

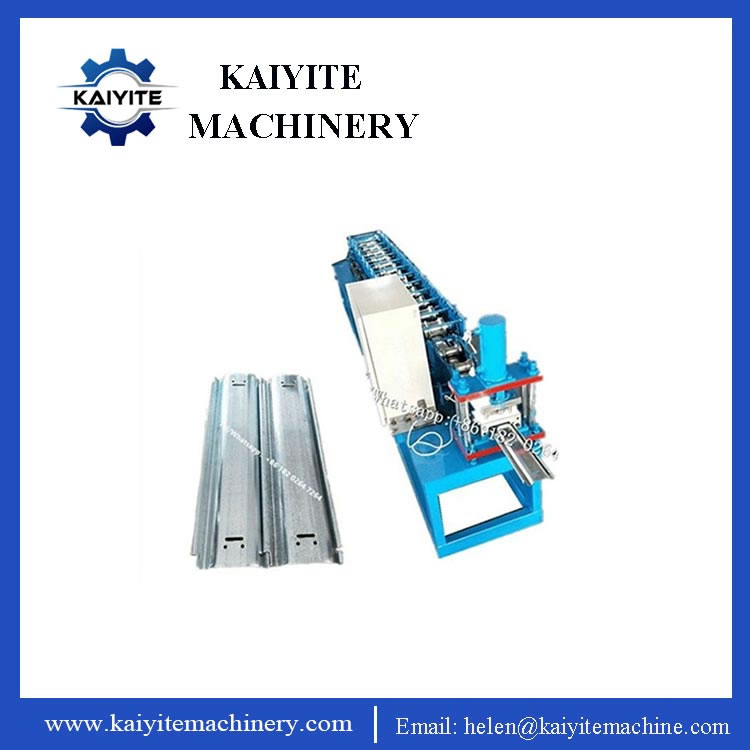

Roller Shutter Door Strip Stamping Forming Machine

This Roller Shutter Door Strip Stamping Forming Machine adopt gear drived way , so that can make sure the accuracy of formed door salt . According to customer’s requirement , this machine has the function of punching hole , and the cutting with punching work at the same time , in this way can increase the efficiency and make sure working speed . A whole set of shutter door main inculde three parts , shutter door salt and sliding U guide rail with bottom strip . These three part work together composed of a safty door and give customers a safity and warmly environment .

Main Detail Of Roller Shutter Door Strip Stamping Forming Machine

* Suitable Material: Colored Steel Plate, Galvanized Board, Aluminum Plate ect ;

* Thickness: 0.3mm – 1.0mm;

* Driving way: By Gear;

* Forming roller station: 12 rows;

* Flatting rollers : 5 rollers;

* Diameter of shaft: ¢40mm, 45# steel;

* Power: 4 Kw + 4 Kw;

* Roller material: 45# steel , heat treatment and polishing;

* Operate type: Manual and Automatic;

* Working speed: 8-12 m/min;

* Size (L*W*H): about 6200*1250*1510 mm;

* Thickness of Wall Panel:14mm

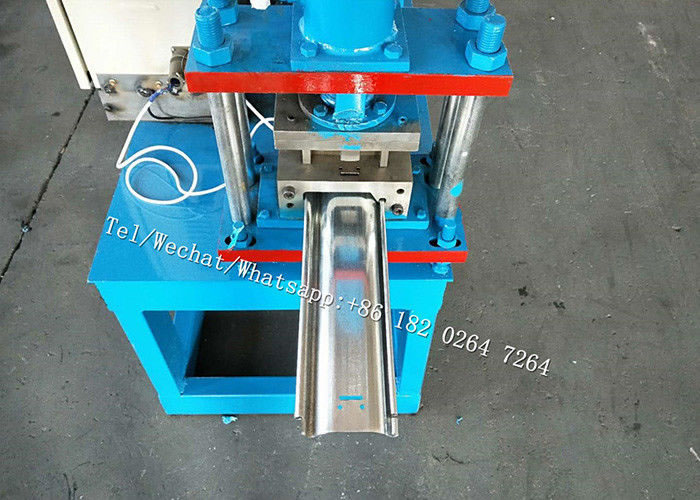

* Cutting Type: Hydraulic Cutting;

* Material of Blade: Cr12 ;

* Voltage: 380V 50Hz 3Phases or Customization;

* Frame: Square Pipe;

* Brand Of PLC: Delta brand with touch screen

Finished Shutter Door Salt

We can design machine according to customer’s requirement .

Working Flow Of Semi-automatic Shutter Door Salt Roll Forming Machine

3 Tons Decoiler — Feeding and Guiding Table — Main Roll Forming Machine — PLC Control System — Hydraulic Cutting Device — Product Receiving Table

Component Of Anti-Wind Shutter Door Roll Forming Machine

* 3 Tons Manual Deciler………………………………..1 Unit

* Main roll forming system………………………..1 Unit

* Hydraulic system…………………………….1 Unit

* PLC Control Cabinet………………………………1 Unit

* Shutter Door Salt Receiving table…………………….2 Unit

* Spare Part…………….1 Unit

Advance of Anti-Wind Shutter Door Roll Forming Machine

* High performance * No noise * Low cost

* 5 Years warranty * Long working life * Easy to operate

* High quality * Full Automatic * Pass ISO9001/CE

* Accurate * Teda brand PLC * Touch Screen

* Gear Drived * Two Operat Language

More Different Shape Of Shutter Door Salts

If there are any kind of shutter door salt that you like , please teel us freely . We also accept customerized .

Other Related Machine

Sliding U Guaid Raill Roll Forming Machine

Shutter Door Bottom Strip Roll Forming Machine

A whole set of shutter door main inculde three parts , shutter door salt and sliding U guide rail with bottom strip . These three part work together composed of a safty door and give customers a safity and warmly environment .

Application

The shutter door salt produced by Semi-automatic Shutter Door Salt Machine are against fading , resistant to rust , and be widely used in shops , working departments , warehouses , and fire partition. Its strength is three times higher than aluminum alloy door . In a world , it has a large market .

Contact Us

24 hourse service the world .