Detailed Product Description

Basic Info

| Model No.: KYT | Tile Type: Colored Steel |

| Certification: SGS, CE, ISO | Condition: New |

| Customized: Customized | Usage: Roof, Wall, Other |

| Transmission Method: Machinery | Place Of Origin: China |

| After-sales Service Provided: Engineers Available To Debug The Machine Overseas |

Brand: KYT |

| Warranty: 24 Months | Package: Packed With Water Proof Paper |

| Deliever Time: Within 45 Days | Certificate: CE/ISO9001 |

| Name: Shutter Door Siding U Guide Rail Machine | |

Additional Info

| Packaging: Seaworthy packing | Productivity: 30 sets per month |

| Brand: KAIYITE | Transportation: Ocean,Land,Air |

| Place of Origin: China | Supply Ability: 30 sets per month |

| Certificate: ISO9001 | HS Code: 8455221000 |

| Port: Tianjin Port,Shanghai Port | |

Product Description

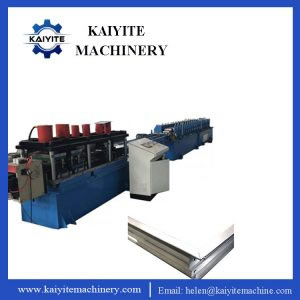

Mute Orbit Roll Foming Machine For Shutter Door

The mute orbit roll forming machine is used to produce the side guide rail for the shutter door . The shutter door profile can be up and down straightly along with the guide rail .

Some client would like to insert some gum strip on the guide rail , so that there will be low noise even slienced when the shutter door goes up and down . Just like the following picture (client sample ).

For the whole Roller Shutter Door Machine , It includes the decoiler , main shutter door equipment , receiving table , oil pump and the PLC control box .

Finished Production For the Roller Shutter Forming Machine

Shutter Door Siding U Guide Rail Roll Foming Machine

3.5T Decoiler — Feeding Table — Main Roll Forming Machine — PLC Control System — Hydraulic Cutting — Product Receiving Table

Main Technical Parameters Of Sliding U Shape Door Guide machine

Raw material

Type: colored steel plate, galvanized plate, or aluminium plate

Thickness: 0.5—1.5 mm (As customer`s need)

Material hardness: 550 Mpa—350 Mpa

Material width: According to customer`s profile

Decoiler

Max width: 300mm (According to customer`s profile)

Inner diameter: 450-650mm (According to customer`s profile)

Max Loading capacity: 2 T

Main roll machine

Working efficiency: 12-15m/min

Forming by rolling: Roll 21 rows (Final rollers depend on the design)

Roller material: Gcr12MoV quenched

Shaft material: 45#steel processing

Diameter of shaft: ¢50mm (Final rollers depend on the design)

Main part power: 7.5kw (Depend on the thickness of material and size of machine)

Hydraulic motor power: 4kw (Depend on the thickness)

Scissor material: Gcr12MoV quenched

Roller material: Gcr15MoV

Voltage: 380V, 50HZ,3 phase (As customer`s need)

Transmission: Gear (Chain and gear box depend on thickness and customer`s need)

We can design machine according to customer’s different requirement.

Different Type of Steel U Guide Raile

Application for the Roller Shutter Door Forming Machine

Shutter door is main made up of U guaid rail, shutter door salt and bottom guaid. As a very important part, U guaid rail need work with shutter door salt and bottom guide. It usually install in the two side of the door, and help the shutter door salt easy up and down ( Open and close ). Shutter Door is widly used in the shop , warehouse , carport and so on . The shutter door can better protect your house from wind , rob , fire ect . It can give your house a more safe condition .

Packing And Loading of the Roller Shutter Door Roll Forming Machine

* The Shutter Door Siding U Guide Rail Roll Forming Machine need 1*20 GP container to load .

* The whole machine will packed water proof paper , ane we will paint oil on the roller and shaft .

* We will fix machine with container by steel wire rope to ensure it not damage when shaking on sea .

* We will take photos and videos for customer when loading to container .

Clients Visit

Welcome all the friends from all over the world to visit us . We can have a meet face to face , what’s more , you can know us and our factory better .

Contact Us

If you want to learn more about this machine or has any questions , please contact us freely .