Detailed Product Description

Basic Info

| Model No.: KYT | Tile Type: Colored Steel |

| Certification: SGS, CE, ISO, Other | Condition: New |

| Customized: Customized | Usage: Other |

| Transmission Method: Machinery | Name: Galvanized Window Frame Roll Forming Machine |

| Control System: PLC | Cutting Type: Hydraulic Cutting |

| Certificate: ISO9001/CE | Material Of Cutting Blade: Cr12 Heat Treatment |

| Place Of Origin: China(Mainland) | Warranty: 18 Months |

| Aftersale Service: Engineer Can Maintain Machine Overboard | Packing: By Water Proof Paper |

| Deliever: Within 45 Days | |

Additional Info

| Packaging: seaworthy packing | Productivity: 30 sets per month |

| Brand: KYT | Transportation: Ocean |

| Place of Origin: China | Supply Ability: 30 sets per month |

| Certificate: ISO9001/CE | HS Code: 8455221000 |

| Port: Tianjin Port | |

Product Description

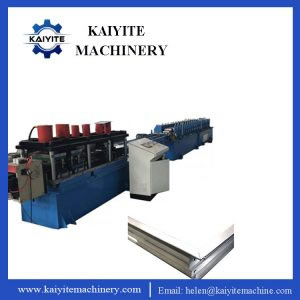

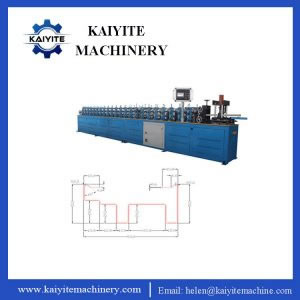

Metal Steel Door Channel Roll Forming Machine

The metal sheet door channel roll forming machine is mainly used to produce the Door Frame Roll Forming Machine .

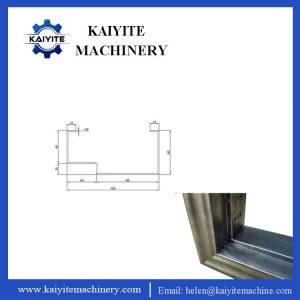

Along with the develpment of the society , more and more businessman prefer to the door frame with pin and hole . This kind of door frame is more convenient to use , because it is no need to weld the two frame . They can bite with each other by the pin and hole . Of course , this kind of production line require more high technology and high accuracy . It has a separated hydraulic punching system .

Finished Product of Galvanized Window Frame Roll Forming Machine

Steel Door Frame Roll Forming Machine Parameter

Below is some details of the door frame machines:

(Machine pictures are for your reference)

First part: 3 Ton hydraulic Decoiler

This part is composed by the following elements: 3 Ton Hydraulic decoiler

3 Ton Hydraulic decoiler:

Loading ability: 3T Max coil width:400mm

Inner diameter:450-508mm outer diameter: Max 1500mm

Forth part: roll forming machine

1.Feature Ensure the stability, accuracy and long life

2.Main forming machine Size 8500mm*1200mm*1500m(L*W*H)

3.Main forming machine weight 7.5Ton

4.Voltage 380V 50Hz 3 Phrase (380 V is China normal voltage, but the voltage can be customize by customer.)

5.Method for fixing roller Memorial arch frame

6.Material of shafts 45# steel Thermal refining

7.Transmission method Gear

8.The main shaft material No. 45 steel quenching and tempering treatment

9.Outer shaft diameter 60mm

10.Wheel material Quenching process of GCr15 bearing steel HRC58-60

11.Roller16 stations

12.The main motor power: 7.5kw

Sixth part hydraulic station

1.Hydraulic oil 46#

2.Hydraulic power 4kw

3.Components The system includes a set of hydraulic tank ,

a set of hydraulic oil pump, two hydraulic pipes.

and two sets of electromagnetism valves

Seventh part PLC Control Device

1.Control By PLC

2.PLC language As required

3.Touch screen Delta

4.Function Automatic length and quantity measurement

5.Include Equipped with movable switch , air break,

radiator, transformer & electric leakage protector for

6.operation convenience and safety.

7.Feature Adopted PLC , transducer, touch panel from

Mitsubishi Japan to ensure high speed with stability,

precision and lifetime.

More Information About Door Frame

Contact us