Detailed Product Description

Basic Info

| Model No.: KYT185-220-270 | Tile Type: Colored Steel |

| Certification: CE, ISO, Other | Condition: New |

| Customized: Customized | Usage: Other |

| Transmission Method: Machinery | Place Of Origin: China(Mainland) |

| Control System: PLC | Production Capacity: 8-10meter/min |

| Thickness Of Raw Material: 0.8-1.5mm | Cutting Type: Hydraulic Cutting |

| Voltage: 380V 50Hz 3Phases Or As Your Required | Roller Material: 45# Forged Steel |

| Material Of Cutting Blade: Cr12 Heat Treatment | Main Body: 350H Steel |

| Shaft Material: 45# Steel, Outer Diameter:80mm | |

Additional Info

| Packaging: Seaworthy packing | Productivity: 30 sets per month |

| Brand: KAIYITE | Transportation: Ocean |

| Place of Origin: China | Supply Ability: 30 sets per month |

| Certificate: ISO9000 | HS Code: 8455221000 |

| Port: Tianjin Port,Shanghai Port | |

Product Description

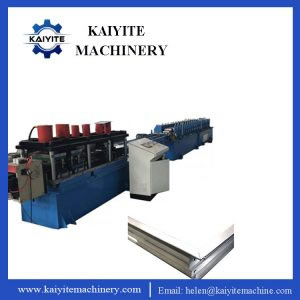

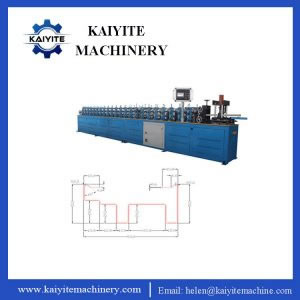

Galvanized Steel Door Guide Rail Roll Forming Machine

Galvanized Steel Door Guide Rail Roll Forming Machine is used to produced steel door or window frame. In actually, the door frame or window frame is a channel which can fix the door or window with the wall closely to make the door and window embed in the wall very strongly.

With the door frame, your door will more strong and your house will be more fastness. It can protect your family and propert well, so your family will have a safity home with it. That is also why so many people is widly used in shop, warehouse and so on.

1. Door Frame Producting Process Flow

Decoiler- Feeding and Leveling device- Main Roll Forming System- PLC Control System- Hydraulic Punching and Cutting device- Discharge table.

2. Machine Parameter

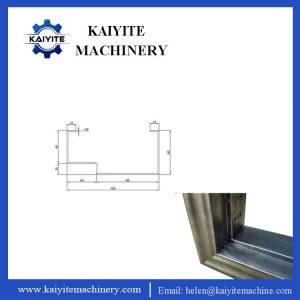

2.1 Raw Material

A. Suitable Material: Colored Steel Plate, Galvanized Board, Aluminum Plate;

B. Width of the raw material: 270 mm;

C. Thickness: 0.8mm – 1.5mm;

2.2 Main Body

A. Roller station: 18 rows;

B. Diameter of shaft: ¢80mm, 45# steel;

C. Roller material: 45# steel;

D. Frame: 350 H steel;

E. Operate: Manual and Automatic;

F. Working speed: 8 – 10 m/min;

G. Size (L*W*H): about 8600*1250*1600 mm;

2.3 Power

A. Motor power: 5.5 Kw, Hydraulic power: 4 Kw;

B. Voltage: 380V 50Hz 3Phases or Customization;

C. Driving way: 1.5 inch Chain

3. Components of machine

* Manual Deciler………………………………..1 Unit

* Feeding Table and Leveling Device………………..1 Unit

* Main roll forming system………………………..1 Unit

* Hydraulic system…………………………….1 Unit

* PLC Control Cabinet………………………………1 Unit

* Discharge table…………………….1 Unit

* Spare Part…………….2 Unit

4. Product’s Picture

5. Packing and Shipping

For this machine need 1*40 GP container to load, one container can load 2 sets machines normally.

Before loading to container, we will check and test machine frist.

Second, make some protection on the machine. Such as, we will make the plastic package on the easy damage parts, paint the oil on the roller and shaft, in case the roller and shaft got corrosion and rusty during long time delievery.

Third, we will fix all the parts into container by steel wire rope. And ensure the machine will not damage when shaking on sea.

At last, we will take phoots and videos for customer when loading to container, so that the customer can take out the machine easily when receive the goods.

Company information

Kaiyite machinery is a leading manufacture of roll forming machine . We know well the particular requirements for the customers from different countries , and have an outstanding export team who will take your requests . Our experts and skilled workers complete the work with great precision .

We provide an extensive line of products , including Roller Shutter Door Roll Forming Machine , Door Frame Machine , Roof And Wall Panel Roll Forming Machine , Double Layer Roll Forming Machine ,Floor Deck Roll Forming Machine ,C / Z / U Purlin Roll Forming Machine , Stud And Track Roll Forming Machine , Ridge Cap Roll Forming Machine , Downspout Pipe Roll Forming Machine , Shearing Machine And Bending Machine , Slitting And Cutting Machine .

6. Contact Information