Detailed Product Description

Basic Info

| Model No.: KYT | Tile Type: Colored Steel |

| Certification: SGS, CE, ISO | Condition: New |

| Customized: Customized | Usage: Roof, Wall, Floor |

| Transmission Method: Hydraulic Pressure | Control System: PLC Control |

| After Sale Service: Engineer Available To Service Machine Abroad |

Certificate: CE/ISO9001 |

| Transmission: By Chain | Width Of Material: Accroding To Client’s Request |

| Cutting Device: Hydraulic Cutting | Payment: By T/T |

| Package: With Water Proof Paper | Warranty: 5 Years |

| Product Name: Glazed Roof Sheet Forming Machine | |

Additional Info

| Packaging: Main machine is packed with water proof paper, the computer control box is packed by carton box |

Productivity: 30 sets per month |

| Brand: KYT | Transportation: Ocean,Land,Air |

| Place of Origin: China | Supply Ability: 30 sets per month |

| Certificate: ISO9000/CE | HS Code: 8455221000 |

| Port: Tianjin Port | |

Product Description

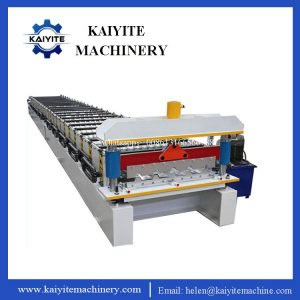

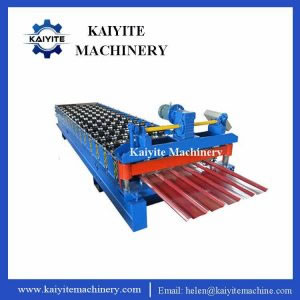

Europe Type Roofing Sheet Roll Forming Machine

Europe type roofing sheet roll forming machine plays a fairly important role in the steel struction building filed . This kind of Europe type roofing sheet roll forming machine can produce very beautiful and durable roofing and wall panel . With these roof and wall panel , it can protect your roofing of house well and give you a safty & warmly home . In a world , it has a very large market .

Main Specification Of Trapezoidal Tile Roll Forming Machine

| No. | Type | Specification | |

| 1 | Row Material | Type | Aluminum / Steel / Galvanized Panel |

| Feeding width | According to client’s requirement | ||

| Thickness | 0.3-0.7mm | ||

| 2 | Main body | Roller station | 12 Steps (According to the profile) |

| Diameter of shaft | ¢75mm | ||

| Shaft material | 45# Steel | ||

| Roller material | 45# Steel | ||

| Frame | 350mm H Steel | ||

| Frame thickenss | 18 mm | ||

| Operation | Manual and Automatic | ||

| Working speed | 8-12m/min | ||

| Size (L*W*H) | About 7600*1550*1510mm | ||

| Weight | About 3.5 Tons | ||

| Cutting type | Hydraulic cutting | ||

| Material of blade | Cr12, HRC60-62°C | ||

| 3 | Power | Motor power | 4 kw |

| Hydraulic power | 4 kw | ||

| Voltage | 380V 50Hz 3phases or Customerization | ||

| Driving way | By Chain | ||

Working Flow Of Trapezoidal Tile Roll Foming Machine

5 Tons Decoiler — Panel Feeding And Guiding Table — Main Roll Forming Machine — PLC Control System — Hydraulic Cutting Device — Product Receiving Table

Component of Trapezoidal Tile Roll Foming Machine

* 5T Decoiler………………………………1 Set

* Feeding Table………………………………1 Set

* Main Roll Forming Machine………………………………1 Set

* PLC Control System………………………………1 Set

* Hydraulic Cutting………………………………1 Set

* Discharge Table………………………………2 Set

Finished IBR Roofing Sheet

We can design machine aoocrding to client’s requirement.

More Different Profile Of Trapezoidal Tile For Your Reference

We can design machine according to customer’s requirement or profile drawing.

Machine Feature

* Full automatic * Lower cost * High efficiency

* Reliable working * 5 Years Warranty * Easy Operate

* Low energy consumption * Accurate * Passed ISO9001/CE

Application

This type of sheet play a very important role in the steel structure building . It is widly used in warehouse, workshop, roofing and other part. In a word , it has a large market.

Loading And Shipping

* We will packed water proof paper on the machine .

* This trapezoidal tile roll forming machine need 1*40 GP container to load .

* Fix machine by steel wire rope, to ensure it will not damage when shaking on sea.

* We will take photos and videos for customer when loading to container .

Clients Visit

Welcome all the friends from all over the world to visit us . We can have a meet face to face , what’s more , you can know us and our machine better .

Contact Us

If you want to know more about this machine, please contact us freely.