Detailed Product Description

Basic Info

| Model No.: KYT | Place Of Origin: China |

| After-sales Service Provided: Engineers Available

To Debug The Machine Overseas |

Brand: KYT |

| Warranty: 18 Months | RAW MATERIAL: Colored Steel Sheet,

galvanized Steel Sheet |

| Control System: PLC | Voltage: As Your Required |

| Cutting Type: Hydraulic Cutting | Thickness Of Raw Material: 0.4-0.8mm |

| Product Name: Light Steel Keel Roll Forming Machine | |

Additional Info

| Packaging: Seaworthy packing | Productivity: 30 sets per month |

| Brand: KAIYITE | Transportation: Ocean,Land,Air |

| Place of Origin: China | Supply Ability: 30 sets per month |

| Certificate: ISO9001 | HS Code: 84552210 |

| Port: Tianjin Port,Shanghai Port | |

Product Description

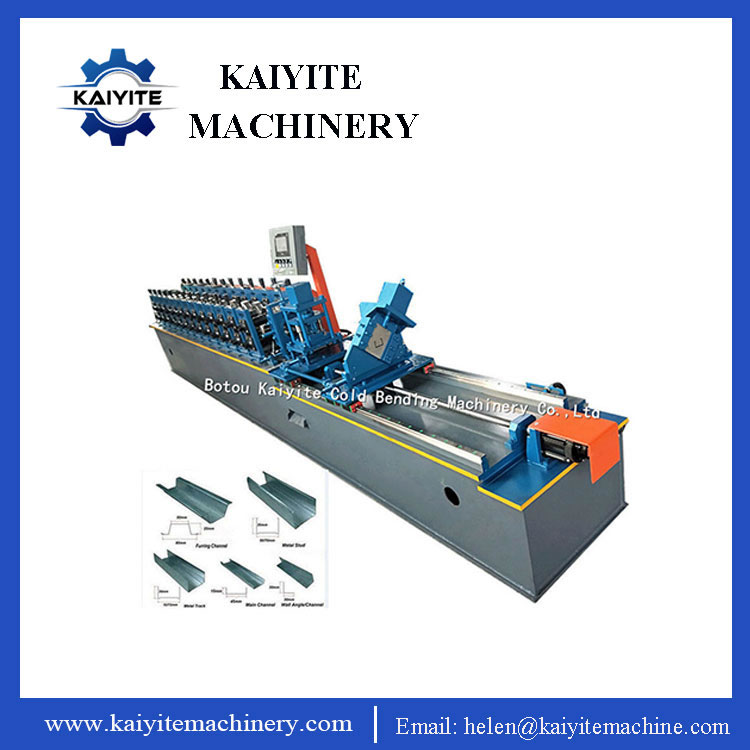

Drywall Stud Roll Forming Machine

The drywall stud roll forming machine can make the different size of C and U profile at only one machine . As it has the spacer between the rollers , we just need to change the spacers then we can get different size of the profile . There is hole on the c profile , normally the hole has H shape , round shape and oval shape according to the client requirement . The thickness of the raw material can be from 0.3-0.7mm . The speed of the stud roll forming machine is about 40 meter/ min . If you want much faster speed , we can also design for you . The fastest Light Keel Roll Forming Machine can reach 80 meter /min .

What is the advantage of the Stud And Track Roll Forming Machine ?

●Fully automatic . The machine is total automatic , just need to set the data on the touch screen , then it can work automaticly . it just need two ●worker to operate .

●No-stop cutting system . The cutting system of the machine is hydraulic tracking cutting , it can highly imporve your productivity .

●Multi-size. The machine can produce several size , we can change the size by adjusting the spacer .

How it benefit the client from the advantage ?

●Save labor cost . As the machine is fully automatic , it just need two workers to operate . Surely it can save labor cost .

●Improve your productivity . the machine is no stop cutting system , its speed can reach 60 meter per minute so it can highly imporve your ●productivity . It can help you get more order and them imporve your profit .

●Save space and cost . This machine can produce several size panel , so it save your space and cost .

What is the application of the stud and Track Roll Forming Machine?

●Because products has smooth appearance beautiful appearances, uniform lacquer veins, high strength, durable, widely used in decorating the ceiling and wall for industrial and civil buildings, such as workshop, warehouse, locomotive shed, hangar room, gymnasium, exhibition halls, theaters and other surface and wall .

What is the parameter of the stud and track roll forming machine ?

| Stud and track roll forming machine | ||

| Raw Material | raw material | Galvanizes strip |

| Thickness of raw material | 0.3-0.8mm | |

| Main machine | Main motor power | 7.5 kw |

| Forming Steps | 12 steps | |

| Shaft material | 45# quenched | |

| Shaft diameter | 50mm | |

| Roller mateiral | 45# hard chromed plated | |

| Transmission | gear wheel | |

| Forming speed | 50-60 meter/min | |

| Cutting system | Cutting | Hydraulic tracking cutting |

| Blade material | Cr12 | |

| Pump power | 4kw | |

| PLC | PLC | Panasonic |

The detailed pictures of the Steel Stud Roll Forming Machine .

Factory show

Kaiyite machinery is a leading manufacture of roll forming machine . We know well the particular requirements for the customers from different countries , and have an outstanding export team who will take your requests . Our experts and skilled workers complete the work with great precision .

We provide an extensive line of products , including shutter door machine , Door Frame Machine , roof and wall panel machine , Floor Deck Roll Forming Machine ,stud and track roll forming machine

Purlin forming machine , tile roof machine , floor decking machine and other associated equipment .