Detailed Product Description

Basic Info

| Model No.: KYT | Product Name: Aluminium Trapezoidal Roof And Wall Panl Machine |

| Control System: PLC Control | After Sale Service: Engineer Available To Service Machine Abroad |

| Certificate: CE/ISO9001 | Transmission: By Chain |

| Warranty: 18 Month | RAW MATERIAL: Colored Steel Plate;Galvanized Board; Aluminum Pla |

| Thickness Of Material: 0.3-0.7mm | Width Of Material: Accroding To Client’s Request |

| Cutting Device: Hydraulic Cutting | |

Additional Info

| Packaging: Main machine is packed with

water proof paper, the computer control box is packed by carton box |

Productivity: 30 sets per month |

| Brand: KAIYITE | Transportation: Ocean,Land,Air |

| Place of Origin: China | Supply Ability: 30 sets per month |

| Certificate: ISO9001/CE | HS Code: 8455221000 |

| Port: Tianjin Port | |

Product Description

Corrugated Plate Roll Forming Machine

The corrugated plate roll forming machine is produced for the Guatemala client . The Roof Panel Roll Forming Machine is total automatic controlled by the computer . Because of its feature , it just need one or two workers to operate . In some way , the client can save much cost on the labour . When the client received the roof roll forming machine , please add the the oil for the hydraulic pump and connect the line according to the layout which will be shipped to you together with the machines .

Main Parameter Of Metal Roof Roll Forming Machine ?

| 1 | Dimensions (L*W*H) | 6200*1550*1510mm |

| 2 | Total power | Motor power:4kw Hydraulic power:4kw |

| 3 | Rows of rollers | 12 Stations |

| 4 | Productivity | 10-15m/min |

| 5 | Diameter of shaft | 75mm |

| 6 | Voltage | 380V 50hz 3phases |

| 7 | Machine body | 300mm H beam |

| 8 | Middle plate | 16mm |

| 9 | Weight | About 3 ton |

| 10 | Chains | 1.5 inch |

| 11 | Roller material | 45# steel plated with chrome |

| 12 | Shafts material | 45# steel |

| 13 | Cutting blade material | Cr12 with quenching treatment |

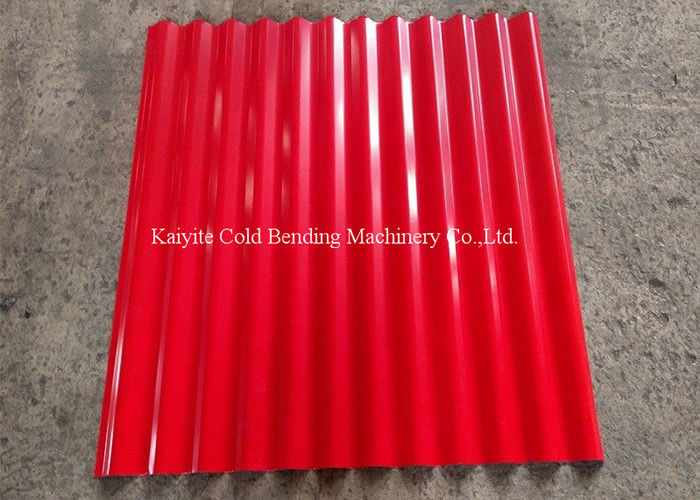

Finshed Product for the Metal Roofing Panel Machine

Working Flow for the Metal Roof Roll Forming Machine

5 Tons Decoiler — Panel Feeding And Guiding Table — Main Roll Forming Machine — PLC Control System — Hydraulic Cutting Device — Product Receiving Table

Machine Feature

* Low Cost * High efficiency * 18 Months Warranty

* Reliable working * Low energy consumption * Easy to operate

* Long working life * Accurate * Full automatic

* No noise * High Quality ( Pass ISO9001/CE)

Some Other type Of Roof And Wall Panel Roll Forming Machine

There are some other type of corrugated tile for customers reference . If you want to other profile , pls contact us , we accept customerzed and can design machine according to client’s requirement .

Application for the metal roofing panel machine

Different roof panel machines can produce different shapes of steel roof, wall sheets according to the clients’ profile drawings and requirement. Steel roof, wall sheets are new building materials with various thickness and colors. They have many advantages, such as low cost, easy installation, short building period, re-cycle use, beautiful appearance, and are light weight but high strength. They are used as the roof and walls of gymnasiums, airports, theatres, factories, warehouses, garages, exhibition centers, etc.

Clients Visit

Welcome customers all over the world to visit us .

Contact Us for more information of the roof and wall panel roll forming machine

If you want to know more detail about this machine, please contact us freely.