Detailed Product Description

Basic Info

| Model No.: KYT | Tile Type: Colored Steel |

| Certification: SGS, CE, ISO | Condition: New |

| Customized: Customized | Usage: Other |

| Transmission Method: Hydraulic Pressure | Working Speed: 8-15 Meter/min |

| Control System: PLC | Blade Material: Cr12 |

| Warranty: 24 Months | After Sale Service: Engineer Available To Service Abroad |

| Thickness Material: 0.7-1.2mm | Product Name: Fire Rated Shutter Door Making Machine |

| Cutting System: Hydraulic Cutting | RAW MATERIAL: Galvanized Steel, Aluminium Plate |

| Certificate: ISO9001/CE | |

Additional Info

| Packaging: seaworthy packing | Productivity: 30 sets per month |

| Brand: KYT | Transportation: Ocean |

| Place of Origin: China | Supply Ability: 30 sets per month |

| Certificate: ISO9000/CE | HS Code: 8455221000 |

| Port: Tianjin Port | |

Product Description

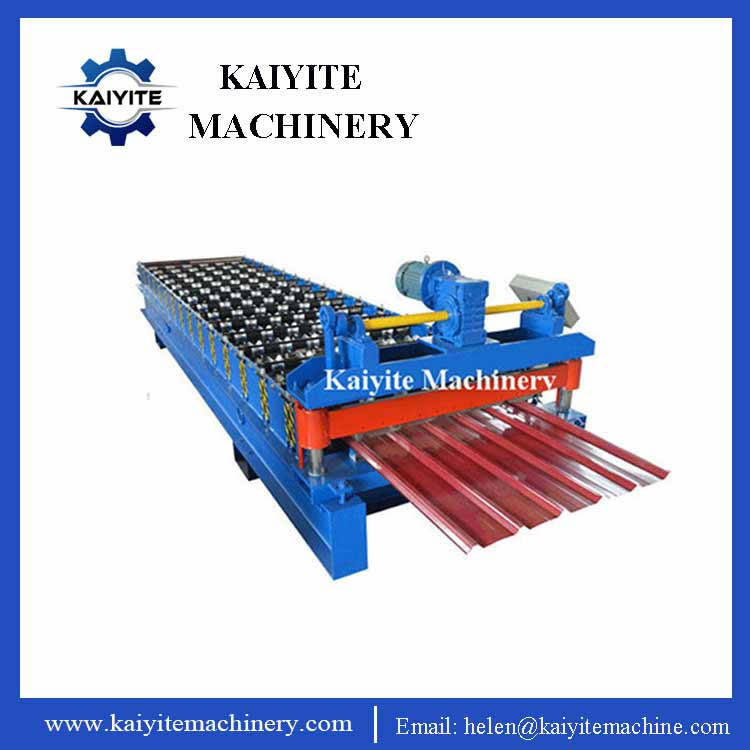

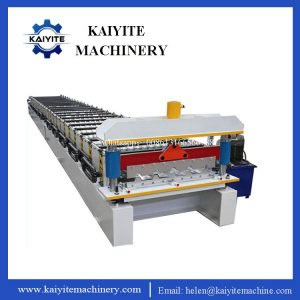

Box Profile Metal Roof Sheet Making Machine

The box profile metal roof sheet making machine is also called trapezoidal roof roll forming machine or IBR sheet roll forming machine .

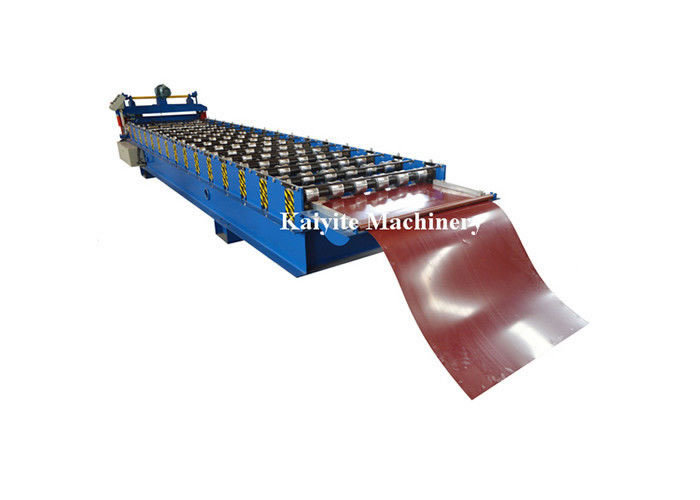

This Roof Panel Roll Forming Machine is composited by the decoiler , main forming system , hydraulic cutting unit , oil pump , PLC control box and out put table .

Normally there are two kinds of wall panel structures, one is separated structure and the other one is whole panel shape . We adopt the transmission type by chain .

The speed of the Roof And Wall Panel Roll Forming Machine can reach 8-12 meter per minute .

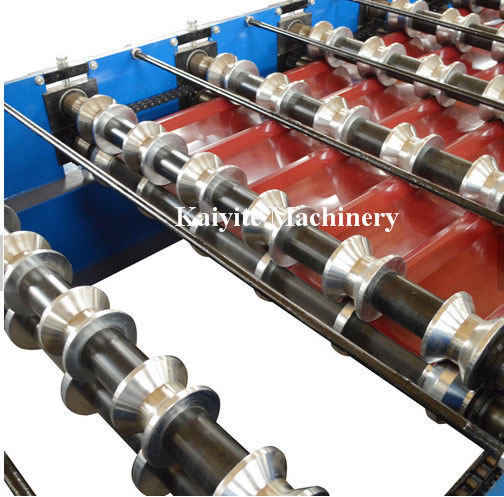

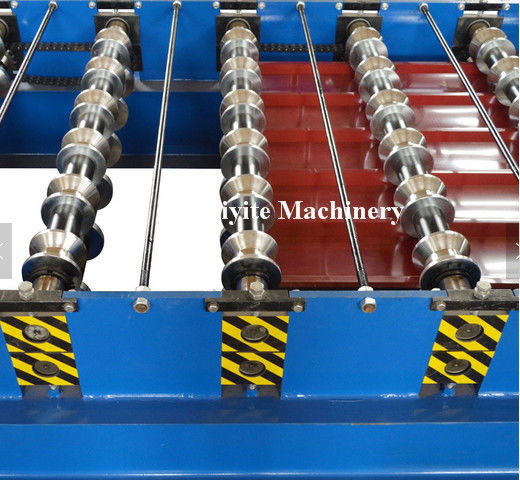

The detailed picture of the roof panel roll forming machine

The parameter of the Metal Roof Roll Forming Machine

Suitable material : colored or galvanized steel coil , HRB 60 or equivalent

Thickness : 0.3-0.8mm

Coil Width : 914 , 1000 ,1220 or 1250 mm according to your actual drawing

Wall panel : separated structure panel

Roller station :20 steps

Transmission type : chain

Roller material :45# hard chromed

Shaft material :45#

Blade material : Cr12

Motor power :5 kw

Hydraulic power :3 kw

Electric power : 380 v 50 hz 3 phase or according to client requirement

The application of the roof sheet produced by the roof panel roll forming machine

The Panels made by our roof panel roll forming machine have beautiful appearance and bright color.

They are widely used in gardens, factories, resorts, hotels, exhibition halls, vacationlands, ancient architectures and modern villas.

Packing and shipping of the Anti-Wind Shutter Door Forming Machine

A. For this Galvanized Fire Rated Roller Shutter Strip Door Machine need 1*20 GP container to load, one container can load 2 sets machines normally. Before loading to container, we will check and test machine frist.

B. Before loading, we will make the plastic package on the easy damage parts, paint the oil on the roller and shaft, in case the roller and shaft got corrosion and rusty during long time delievery.

C. Fix all the parts into container by steel wire rope, to ensure the machine will not damage when shaking on sea.

D. We will take phoots and videos for customer when loading to container, so that the customer can take out the machine easily when receive the goods

Company information

Kaiyite machinery is a leading manufacture of roll forming machine . We know well the particular requirements for the customers from different countries , and have an outstanding export team who will take your requests . Our experts and skilled workers complete the work with great precision .

We provide an extensive line of products , including Roller Shutter Door Roll Forming Machine , Door Frame Machine , roof and wall panel roll forming machine , Double Layer Roll Forming Machine , Floor Deck Roll Forming Machine ,C / Z / U Purlin Roll Forming Machine , Stud And Track Roll Forming Machine , Ridge Cap Roll Forming Machine , Downspout Pipe Roll Forming Machine , Shearing Machine And Bending Machine , Slitting And Cutting Machine .

Contact information for the Roller Shutter Forming Machine