Detailed Product Description

Basic Info

| Model No.: KYT | Tile Type: Colored Steel |

| Certification: SGS, CE, ISO | Condition: New |

| Customized: Customized | Usage: Roof, Wall, Floor |

| Transmission Method: Hydraulic Pressure | Material Of Shaft: 45# |

| Product Name: Double Layer Metal Deck Roof Tile Roll Former | Material Of Rollers: 45# Hard Chromed Plated |

| Control System: PLC Control | Productivity: 8-12 Meter/min |

| Transmission: Chain | After Sale Service: Engineer Available To Service Machine Abroad |

| Warranty: 12 Month | Original: China |

| RAW MATERIAL: Can Help To Supply Raw Material | |

Additional Info

| Packaging: Main machine is nude,the computer control

box is packed by carton box |

Productivity: 30 sets per month |

| Brand: KAIYITE | Transportation: Ocean |

| Place of Origin: China | Supply Ability: 30 sets per month |

| Certificate: ISO | HS Code: 84552210000 |

| Port: Tianjin,Shanghai,Guangzhou | |

Product Description

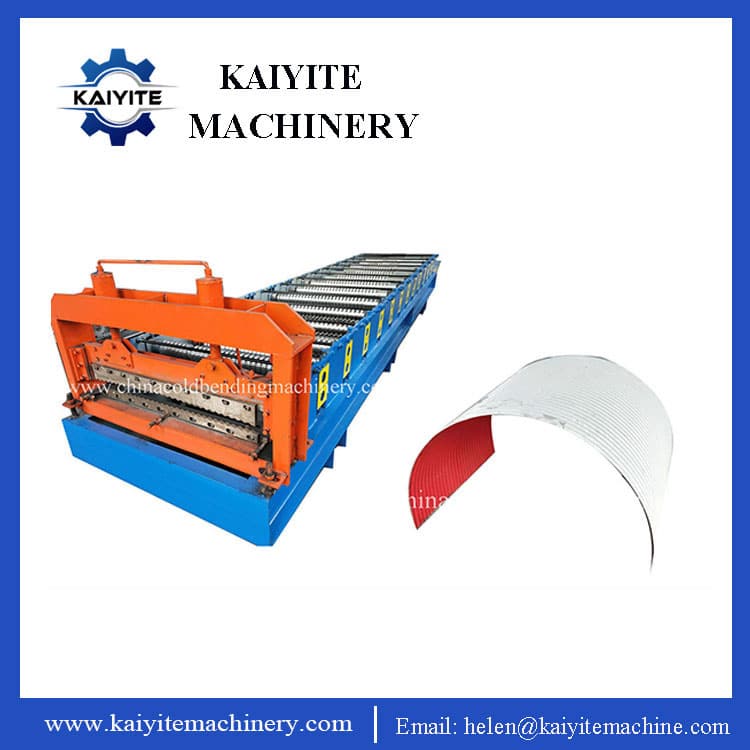

Automatic Dust Cover Corrugated Roll Forming Machine

The automatic dust cover corrugated roll forming machine is usd to protect the product from the wind , rain and sun . This roll forming machine has 13 step stations and the motor is 4 kw . This dust cover roll forming machine should be used together with an Automatic Curving Machine . After the roll forming machine formed the panel , the Automatic Crimping Machine can make it bend . Now we have this machine in stock .

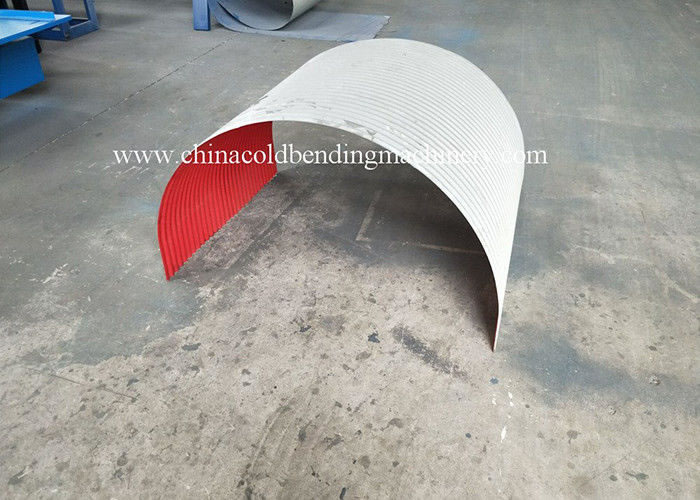

What is your final panel of corrugated roll forming machine ?

The following is the panel shape of the dust cover roll forming machine , if your profile is different from these , please contact with me for more details .

What is the main parameter of the Corrugated Tile Roll Forming Machine ?

| No. | Name | double layer roll forming machine |

| 1 | Roller | roller station :13 Rows |

| 2 | Way of product | Synchronized pressing |

| 3 | Material of the machine body | 300mm H steel |

| 4 | Material | Medium plat:16 mm steel |

| Axle :45# H steel | ||

| 5 | Diameter of th anxles | 70mm |

| 6 | Material of the rollers | 45# H steel plate with chrome |

| 7 | Power | Planetary ruduce:4kw |

| Hydraulic pum :4kw | ||

| 8 | Hydraulic system | CDF-10 gear pump |

| 9 | Control system | PLC control |

| 10 | Thickness of the plate | 0.3-0.8mm |

| 11 | Process precession | within 2mm |

| 12 | Weight | About 3.9 T |

| 13 | Dimension | 6000*1350*1350mm |

| 14 | Production rate | 8-12m/min |

| 15 | Transmission | sprocket chain |

| 16 | Cutting | Hydraulic type |

| 17 | Material of cutting blade | Cr12 |

How do you think about our quality of the Roof And Wall Panel Roll Forming Machine ?

When we take photo for the machine , the light is not very good , so it seems a little dim . But actually the machine will be better once you see it .

Such as the following :

1. what space do we need for the roll forming machine

2. the distance of between the roll machine body and decoiler

3. How to install the steel coil with the manual decoiler

4. how to adjust the distance of the upper and down shaft

5. How to cut the steel coil when finish the working

6. How to set the numbers in control box

7. How to connect the wiring of roll forming machine

8. what kind of hydraulic oil should be filled in hydraulic motor box

9. How many oil should be filled in box

10. The machine not work automatically.

11. The cutter not goes up when cut the panel

12. the panel goes a wrong way in roll forming machine body, not form in one line

13. Client changed the parameter of encoder, i help them to change the parameter

14. the panel not stop when reach the length

15. Motor oil leakage

16. How to adjust the forming speed of roll forming machine

Contact Us