Detailed Product Description

Basic Info

| Model No.: KYT | Working Speed: 8-15 Meter/min |

| Control System: PLC | Blade Material: Cr12 |

| Warranty: 24 Months | After Sale Service: Engineer Available To Service Abroad |

| Thickness Material: 0.7-1.2mm | Product Name: Fire Rated Shutter Door Making Machine |

| Cutting System: Hydraulic Cutting | RAW MATERIAL: Galvanized Steel, Aluminium Plate |

| Certificate: ISO9001/CE | |

Additional Info

| Packaging: seaworthy packing | Productivity: 30 sets per month |

| Brand: KYT | Transportation: Ocean |

| Place of Origin: China | Supply Ability: 30 sets per month |

| Certificate: ISO9000/CE | HS Code: 8455221000 |

| Port: Tianjin Port | |

Product Description

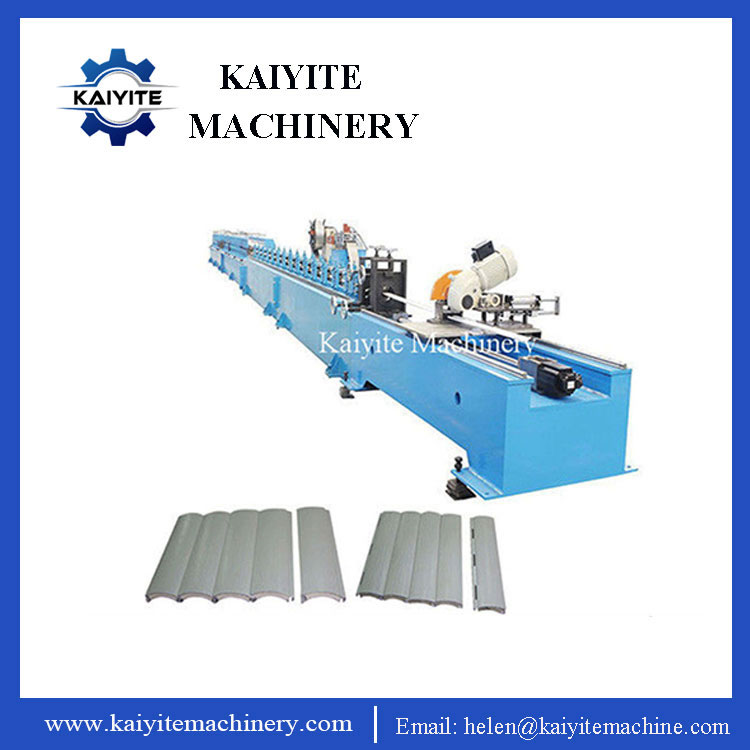

Aluminum 41 & 55 PU Shutter Door Machine

The aluminum 41 & 55 PU Shutter Door Machine is a fully automatic equipment to produce the shutter door profile . It consists the decoiler , main forming part , heated system , and pu form part , punching system , non stop cutting system , output table .There are polyurethane foam inside the shutter door profile . Insulation shutter profiles are roll-formed and filled with fluorocarbon-free polyurethane insulation foam . Polyurethanes are ecological and do not contain harmful substances that destroy the ozone layer . Aluminum alloys and fillers can be recycled and recycled , making them environmentally friendly . Polyurethane foam has a thermal conductivity of about 0.025 . Even at -10°C , it retains its superior thermal insulation properties , making it suitable for residential areas with relatively high insulation requirements as well as hot summer and cold winter areas .

The following is one drawing of the shutter door profile :

The detailed parameter of the Shutter Door Roll Forming Machine

1.Un-coiler

Capacity: 3 tons

Material: #45 steel quenched

Power:2.2KW,03 Phase, 220/380V, 50HZ/60HZ

Method of open and close of segments: manual

Number of segments:4 pieces

Range of segment expansion: ø480- ø520

Inner diameter of coil: ø508

Maximum outer diameter of coil: ø1,300

Feeding speed:25m/min(transducer control)

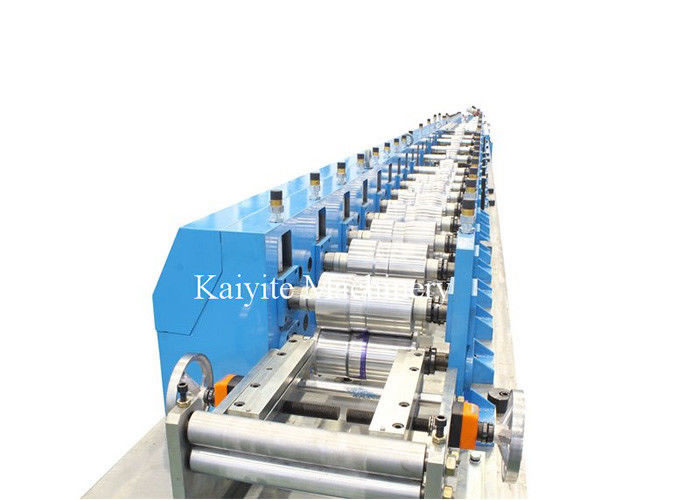

2.Main roll former

Stations: 30

Rollers material: CR 15, HRC 60. Chrome coated: 0.03-0.05mm, Strength (MPA): 70 tons, 800 MPA

Shaft: diameter 50mm, material is #45 steel. Quenched hot treatment. Strength of the main shaft (MPA): 70 tons, 650MPA

Bearing brand: FAG Germany

Main motor: 15KW, 220V, 50HZ, 3 Phases (Siemens Brand)

Transmission by gear

Station material: cast steel

Machine have cover

3.PLC control cabinet

Touch screen brand: Siemens

PLC brand: Siemens

Inverter brand: Delta

Main components for low pressure electricity: Schneider Germany

Encoder: Omron

Sensor: Balluff B+F brand

Control motion/production process: Un-coiler—roll forming—preheating—Injection of polyurethane—Heat preservation—roll forming—correction—Heat preservation—cutting by servo motor— Automatic feeding platform—Mechanical punching—output

4.Cutting platform

Cutting type: Flying saw cutting by Servo motor

Motor: 2.2KW; 380V; 50HZ; 3 Phase

Servo motor: 1.5kw; 220V

Tolerance of length:±1mm

Action: The host does not stop, Servo tracking to cut off

The Knives material: Wolfram 9

5.Punching platform

Total power:7.5Kw

Mechanical punching

Punching pin material:Cr12Mov

Automatic Lubrication system

6.Foam Machine Parameters

Motor power: total 7KW; 380V; 50HZ

Mixing pump quantity: 8g/Second

Density: 35 ~ 40 kg/m³

Mixing type: mechanical & automatic

Washing: Automatic

Tank volume: 50 KG / tank. Both Poly and ISO

Brand of Foam machine: GREAT WALL.

Size (LxWxH):1100mm×1100mm×2000mm

Mixing head with one spare is included

7.Feeding system

Feeding by Rubber: 2KW, 220V/380V(Delta brand from Taiwan)

6M feeding

8.Output table

Length: 8 meters

Automatic discharge cargo

Working type: pneumatic

Drive type: rollers

9.Input material

Material: aluminum sheet

Thickness: 0.3-0.33mm

10.Dimension (L*W*H)

Roll forming machine space: 22m*1.55m*1.36m

Suggest working space:30m*3m*3m

11.Working speed

25-30m/min (including cutting and punching)

12.Include the following normal consumable spares

Bearing in main shaft: 50 pcs

Other bearing (sub-rollers): a feLimit switch:5 pcs

Low pressure electricity: a few

Relay:10 pcs

Connector: a few

Cutting knives: 2 extra

Upper shaft and down shaft: 2 pieces

Station: 2 pieces

Gear: 4 pieces

Company information

Kaiyite machinery is a leading manufacture of roll forming machine . We know well the particular requirements for the customers from different countries , and have an outstanding export team who will take your requests . Our experts and skilled workers complete the work with great precision .We provide an extensive line of products , including Roller Shutter Door Roll Forming Machine , Door Frame Machine , Roof And Wall Panel Roll Forming Machine , Double Layer Roll Forming Machine , Floor Deck Roll Forming Machine ,C / Z / U Purlin Roll Forming Machine , Stud And Track Roll Forming Machine , Ridge Cap Roll Forming Machine , Downspout Pipe Roll Forming Machine , Shearing Machine And Bending Machine , Slitting And Cutting Machine .

Contact information for the Roller Shutter Forming Machine