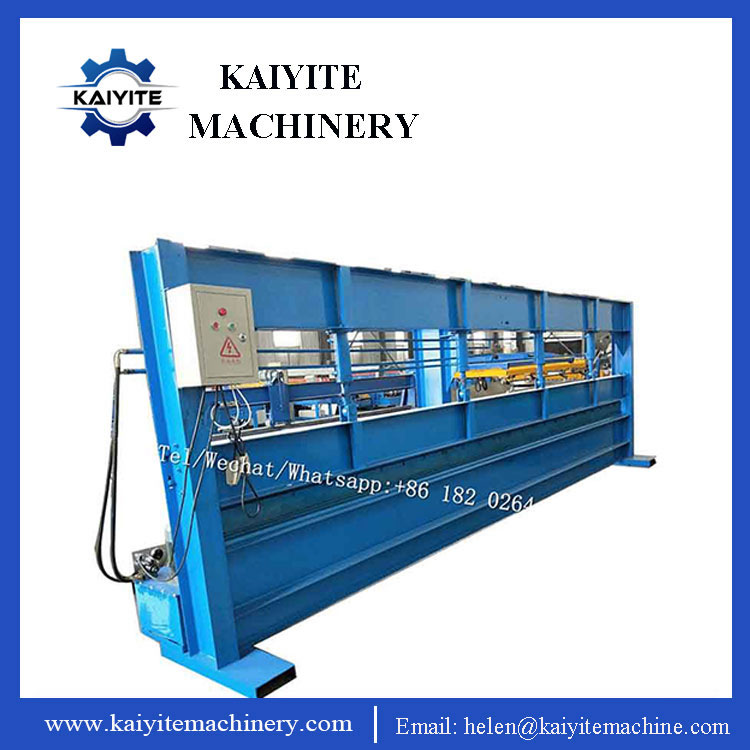

6m Hydraulic Steel Plate Press Machine

Basic Info

| Model No.: KYT15-940-1220 | Tile Type: Colored Steel |

| Certification: SGS, CE, ISO | Condition: New |

| Customized: Customized | Usage: Roof, Wall, Other |

| Transmission Method: Machinery | Place Of Origin: China |

| After-sales Service Provided: Engineers Available To Debug The Machine Overseas | Delivery Time: In stock |

| RAW MATERIAL: Colored Steel Sheet,galvanized Steel Sheet | Control System: PLC |

| Certificate: CE/ISO9001 | Warranty: 5 Years |

| Name: Shutter Door Machine For Sudan Customer | Package: With Water Proof Paper |

Additional Info

| Packaging: Seaworthy packing | Productivity: 30 sets per month |

| Brand: KAIYITE | Transportation: Ocean,Land,Air |

| Place of Origin: China | Supply Ability: 30 sets per month |

| Certificate: ISO9001/CE | HS Code: 84552210 |

| Port: Tianjin Port,Shanghai Port | |

The 6m hydraulic steel plate press machine is widely used for bending steel plate, aluminium board, glavanized panel and so on. Easy to handle and work without noise, reliable performance, beautiful appearance. The hydraulic bending machine has two pedaling plate, one is to control the bending mould to down. One is to control the bending mould rise. You need to step the pedaling plate when you using the machine.

Feature Of Hydraulic Steel Panel Bending Machine

* High Performance * Long Working Life * Low Cost

* 18 Months Warranty * CE/ISO9001 Certificate * No Noise

* Easy Operate ( Full Automatic)

Specification Of Bending Machine

* Suitable Material : Colored steel panel , Galvanized panel , Aluminum panel

* Thickness of sheet : 0.3 – 3.0 mm * Material width : Max 6000 mm

* Switch : Control by foot * Weight of machine : About 1.5 ton

* Power of motor : 3kw * Drive method : Hydraulic drive

* Apprearance size : About 6900mm * 1200mm * 2200mm

* Voltage : 380V 50HZ 3Phases Or Customerization

More Detail Pictures Of Machine

Hydraulic Pump

Limit Switch

PLC Control Box

Pedal Switch

Others

Loading and Shipping

For this machine need 1*20 GP container to load, one container can load 2 sets machines normally.

Before loading to container, we will check and test machine frist.

Second, make some protection on the machine. Such as, we will make the plastic package on the easy damage parts, paint the oil on the roller and shaft, in case the roller and shaft got corrosion and rusty during long time delievery.

Third, we will fix all the parts into container by steel wire rope. And ensure the machine will not damage when shaking on sea.

At last, we will take phoots and videos for customer when loading to container, so that the customer can take out the machine easily when receive the goods.

Contact Us