| Detailed Product Description | |||

| Place Of Original: | China | Brand: | KYT |

| Control System: | Full Automatic | Warranty: | 5 Years |

Basic Info

| Model No.: KYT | Tile Type: Colored Steel |

| Certification: CE, ISO | Condition: New |

| Customized: Customized | Usage: Roof, Wall |

| Transmission Method: Hydraulic Pressure | After Sale Service: Engineer Available

To Service Machine Abroad |

| Control System: PLC Control | Operation Method: Automatic And Manual |

| Valtage: 380V 50Hz 3Phases Or Customerzed | Delivery Time: Within 45 Days |

| Package: Packed With Water Proof Paper | Tranmisstion Mode: By Gear |

| Certificate: ISO9001/CE/SGS | Name: Light Gauge Furring Truss Making Machine |

Additional Info

| Packaging: Seaworthy packing | Productivity: 30 sets per month |

| Brand: Kaiyite | Transportation: Ocean,Land,Air |

| Place of Origin: China | Supply Ability: 30 sets per month |

| Certificate: ISO9001/CE | HS Code: 84552210 |

| Port: Tianjin Port,Shanghai Port | |

Product Description

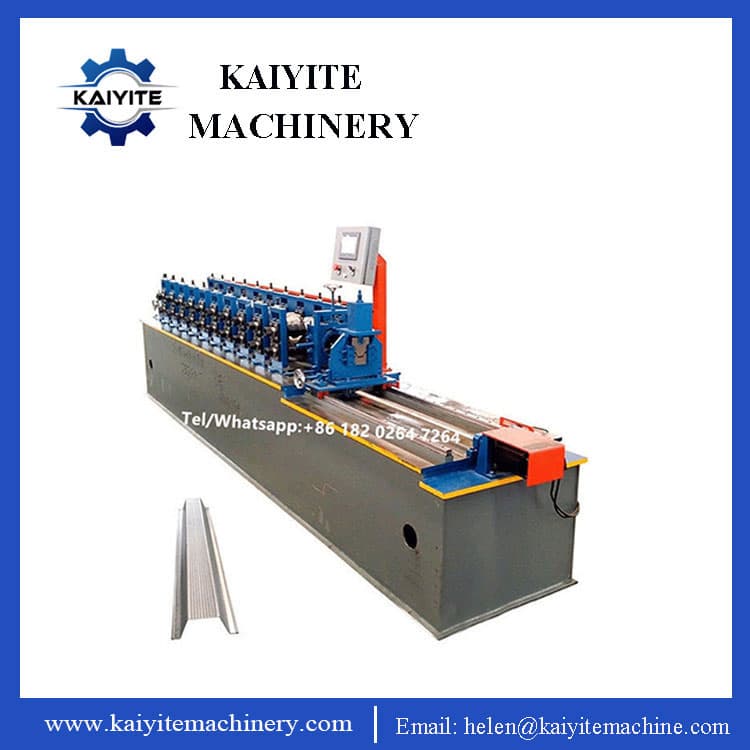

Gypsum Board Ceiling Furring Channel Forming Machine

Nowadays , the Gypsum Board Ceiling Furring Channel Forming Machine is more and more popular in the steel building struction field . Usually , it work with the C stud and U track truss together , and they compose of the whole ceiling . Meanwhile , this machine has high speed ( machine working speed can reach to 40-50m/min ) , it adopts tracking cutting system with high accuracy , in this way can increase the capacity of machine .

Specification Of Gypsum Board Ceiling Furring Channel Forming Machine

* Suitable material: colored steel plate, galvanized plate, or aluminium plate

* Material thickness : 0.3-1.2mm

* Material width : According to the profile

* Material Of Shaft :45# Steel

* Diameter of shaft : 50 mm

* Material Of Roller :45# Steel

* Roller Station : 12 steps

* Sidewall Thickness : 14 mm

* Main frame : 200 H steel

* Motor Power : 3Kw

* Hydraulic Motor : 3kw

* Servo Motor : 1.5Kw

* Weight : About 2 Tons

* Forming speed : 40-50m/min

* Material Of Blade : Cr12

* Cutting device : Hydraulic Cutting

Finished Furring Truss

We can design different machine according to customer’s profile .

Machine Working Flower

Uncoiler — Feeding Table — Main Roll Forming Machine — PLC Control System — No Stop Tracking Cutting System — Products Receiving Table

Component Of Gypsum Board Ceiling Furring Channel Forming Machine

* 5T Decoiler…………………………….1 Set

* Feeding Table………………………………1 Set

* Main Roll Forming Machine………………………………1 Set

* PLC Control System……………………………..1 Set

* Hydraulic Tracking Cutting System………………………………1 Set

* Discharge Table……………………………..2 Set

More Different Profile

Advance of Angle Bar Channel Forming Machine

* High performance * No noise * Low cost

* 5 Years warranty * Long working life * Easy to operate

* High quality * Approve CE/ISO9001 * Full automatic

Application

Usually , the furring truss work with the C stud and U track truss together , and they composed the whole set of ceiling .

Contact Us

24 hourse service the world .

Your kindly inquiry or samply are warmly welcome .

If you want to learn more about this machine or has any questions , please contact us freely .