| Detailed Product Description | |||

| Place Of Original: | China | Brand: | KYT |

| Control System: | Full Automatic | Warranty: | 5 Years |

Basic Info

| Model No.: KYT17-98 | Tile Type: Colored Steel |

| Certification: SGS, CE, ISO | Condition: New |

| Customized: Customized | Usage: Other |

| After Sale Service: Engineer Available To Service Abroad | Package: Packed With Water Proof Paper |

| Delivery Time: Within 35 Days | Certificate: ISO9001/CE |

| Capacity: 8-12m/min | Transmission Method: Electric |

| Warranty: 5 Years | Name: Embossing Pattern Shutter Door Machine |

| Weight: About 2 Tons | |

Additional Info

<td”>Packaging: Seaworthy packing<td”>Productivity: 30 sets per month<td”>Brand: KYT<td”>Transportation: Ocean,Land,Air<td”>Place of Origin: China<td”>Supply Ability: 30 sets per month<td”>Certificate: ISO9000/CE<td”>HS Code: 8455221000<td” colspan=”2″>Port: Tianjin Port

Product Description

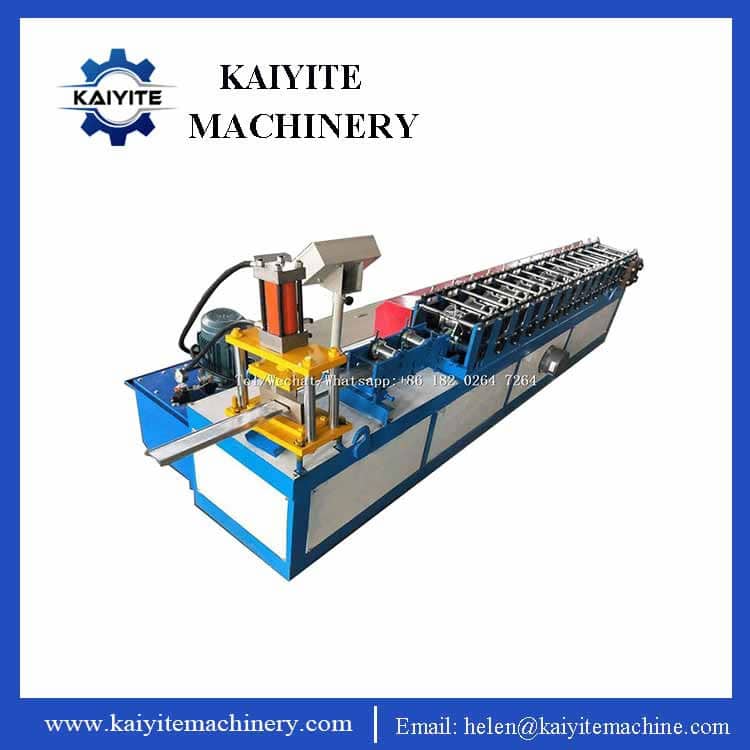

Embossing Pattern Shutter Door Strip Roll Forming Machine

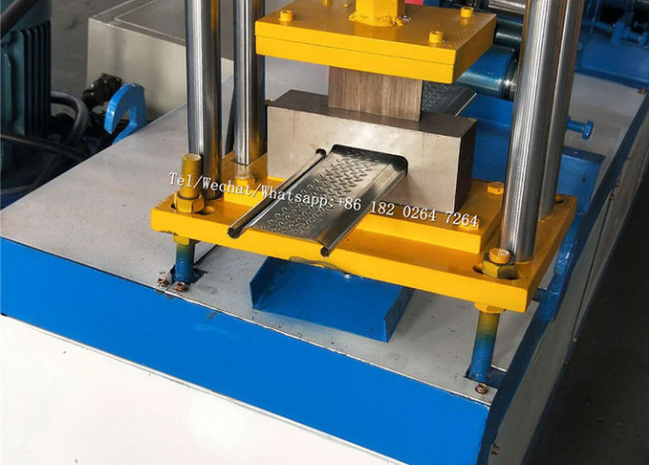

This embossing pattern shutter door strip machine can embossing two different of patterns on the shutter door salt , so that can meet customer’s different aesthetic . Meanwhile, it adopt gear drived to make sure the accuracy and customer can more easily to operate the PLC with the Teda brand touch screen . A whole set of shutter door main inculde three parts , shutter door salt and sliding U guide rail with bottom strip . These three part work together to give customers a safity and warmly environment .

Main Detail Of Embossing Pattern Shutter Door Strip Machine

* Suitable Material: Colored Steel Plate, Galvanized Board, Aluminum Plate;

* Thickness: 0.3mm – 1.0mm;

* Driving way: By Gear

* Forming roller station: 12 rows;

* Flatting rollers : 5 rollers

* Diameter of shaft: ¢40mm, 45# steel;

* Roller material: 45# steel;

* Operate: Manual and Automatic;

* Working speed: 8-12 m/min;

* Size (L*W*H): about 6200*1250*1510 mm;

* Thickness of Wall Panel:14mm

* Motor power: 3 Kw

* Hydraulic power: 3 Kw;

* Cutting Type: Hydraulic Cutting;

* Material of Blade: Cr12

* Voltage: 380V 50Hz 3Phases or Customization;

* Frame: 250 H steel;

* Brand Of PLC: Teda , touch screen

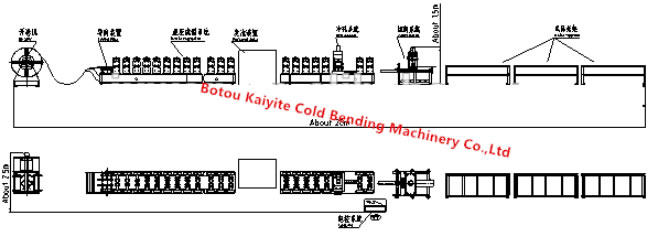

Working Flow Of Anti-Wind Shutter Door Roll Forming Machine

Decoiler — Feeding Table — Main Roll Forming Machine — PLC Control System — Hydraulic Cutting Device — Product Receiving Table

Component Of Anti-Wind Shutter Door Roll Forming Machine

* Manual Deciler………………………………..1 Unit

* Main roll forming system………………………..1 Unit

* Hydraulic system…………………………….1 Unit

* PLC Control Cabinet………………………………1 Unit

* Discharge table…………………….2 Unit

* Spare Part…………….1 Unit

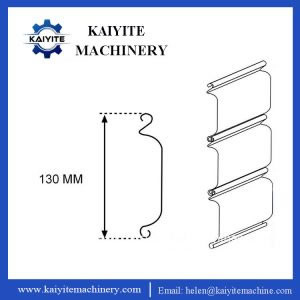

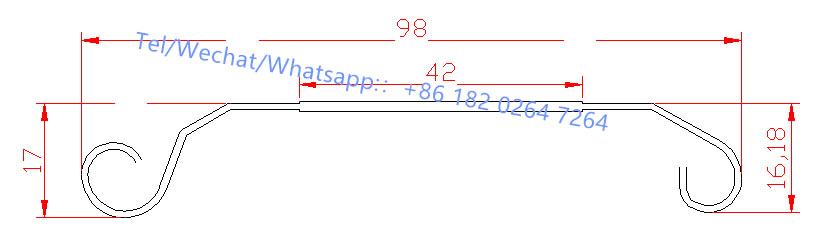

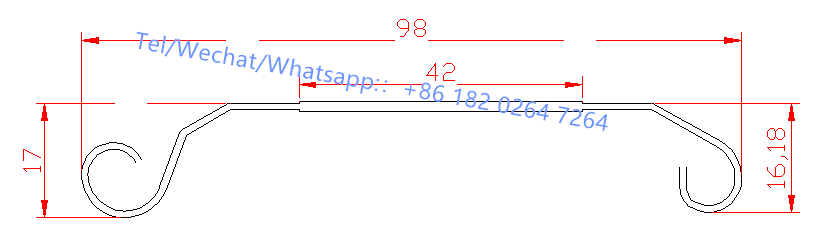

Profile And Finished Shutter Door Salt

We can design different type of shutter door strip according to customer’s requirement.

Advance of Anti-Wind Shutter Door Roll Forming Machine

* High performance * No noise * Low cost

* 24 month’s warranty * Long working life * Easy to operate

* High quality * Full Automatic * Pass ISO9001/CE

* Accurate

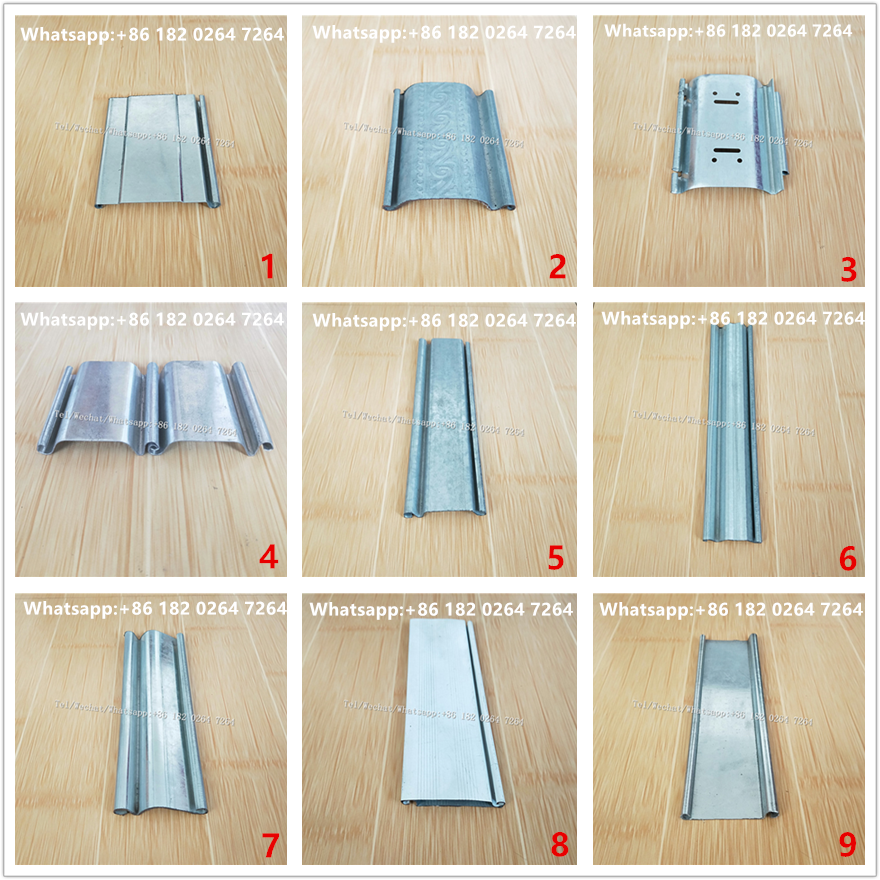

More Different Shape Of Shutter Door Salts

If there are any kind of shutter door salt that you like , please teel us freely . We also accept customerized .

Application Of Embossing Pattern Shutter Door Strip Machine

The products produced by Embossing Pattern Shutter Door Strip Machine are bright in colored , against fading , resistant to rust , and be widely used in shops , working departments , warehouses , and fire partition. Its strength is three times higher than aluminum alloy door . In a world , it has a large market .

Contact Us

24 hourse service the world .

Your kindly inquiry or samply are warmly welcome .

If you want to learn more about this machine or has any questions , please contact us freely .